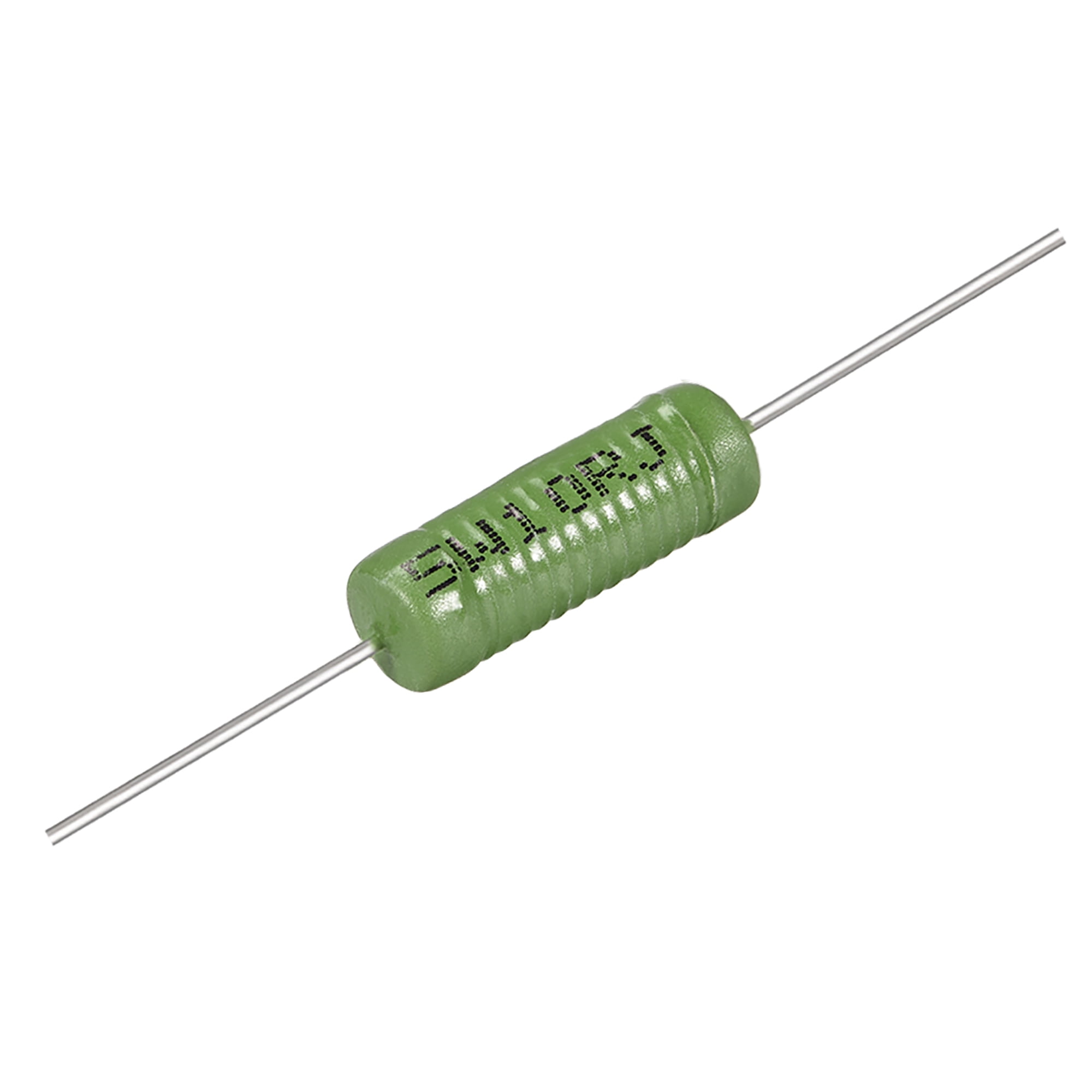

The Cutting-Edge Potential of Wire Wound Resistors

As electronics evolve rapidly, the these resistive components remain critical in numerous settings. More than just a basic electrical component, the wire wound resistor place themselves strategically in many innovations. Join us as we uncover the expansive applications of the wire wound resistor.

Precision and Accuracy: Crucial Attributes

A significant edge provided by the wire wound resistor is their remarkable accuracy. These resistors achieve precision beyond what many counterparts can reach. Their craftsmanship is shown in the winding, allowing a controlled resistance value.

In areas needing acute exactness, such as advanced instrumentation creation, wire wound resistors meet the demand. That feature ensures precise recordings remain stable even during changing environmental conditions.

Power Management and Efficiency

The ability of wire wound resistors to handle immense power results in their broad use-case scenarios. They sustain high power without sacrificing integrity.

Alternative power setups like solar energy frameworks and wind-driven generators utilize this resilience. Turning natural sources into power involves many fluctuating conditions. Wire wound resistors become invaluable assets here, stabilizing electrical signals to achieve desired energy yields.

Resistor Innovations Shaping the Future

The trajectory of electronics influences resistor evolution. Currently, wire wound resistors are combining into connected ecosystems as part of global inter-device connectivity.

Smart grids stand at the forefront of innovation. Wire wound resistors are core in these grids. They offer localized power handling across mass-scale frameworks, achieving electrical harmony. Performance stability is ensured by their role and assist eco-friendly operations.

Decision-Making for Wire Wound Resistor Integration

Choosing the appropriate wire wound resistor for your needs involves understanding the application's demands. The parameters of resistance, usable power, and conditions must be weighed carefully. Looking into Find out more offers straightforward guidance in making the most suitable choice.

Taking care and diligence yields proper component implementation. Besides this, collaborating with suppliers boosts selection accuracy, allowing bespoke resistor configurations that align perfectly with contextual demands.

Where We Go Next with Wire Wound Resistors

In alignment with electronic advances, wire wound resistors will need to innovate. The drive for compact solutions demands design reinventions, requiring compact yet powerful alternating solutions. Advancements in material science could unlock newer materials featuring upgraded operation.

At the same time, collaboration with tech systems could allow real-time tuning of resistor properties, embedding software adaptability. These steps will embody harmonization across hardware—software divides, increasing system efficacy. Visionary engineers are spearheading these transformations, ensuring that wire wound resistors flourish for upcoming generations.