Manufacturing Insights and Future Trends of Wire Wound Resistors

These essential resistors manifest to engineering precision combined with durable performance. Serving as cornerstone elements in a myriad of circuits, these resistors feature prominently within evolving markets. Their journey entails disciplined manufacturing protocols, innovation driven by industry needs, and conformity to dynamic market shifts. We delve into the finely honed engineering practices, market integration, and future possibilities for the wire wound resistors.

Unveiling Engineering Mastery in Wire Wound Resistors

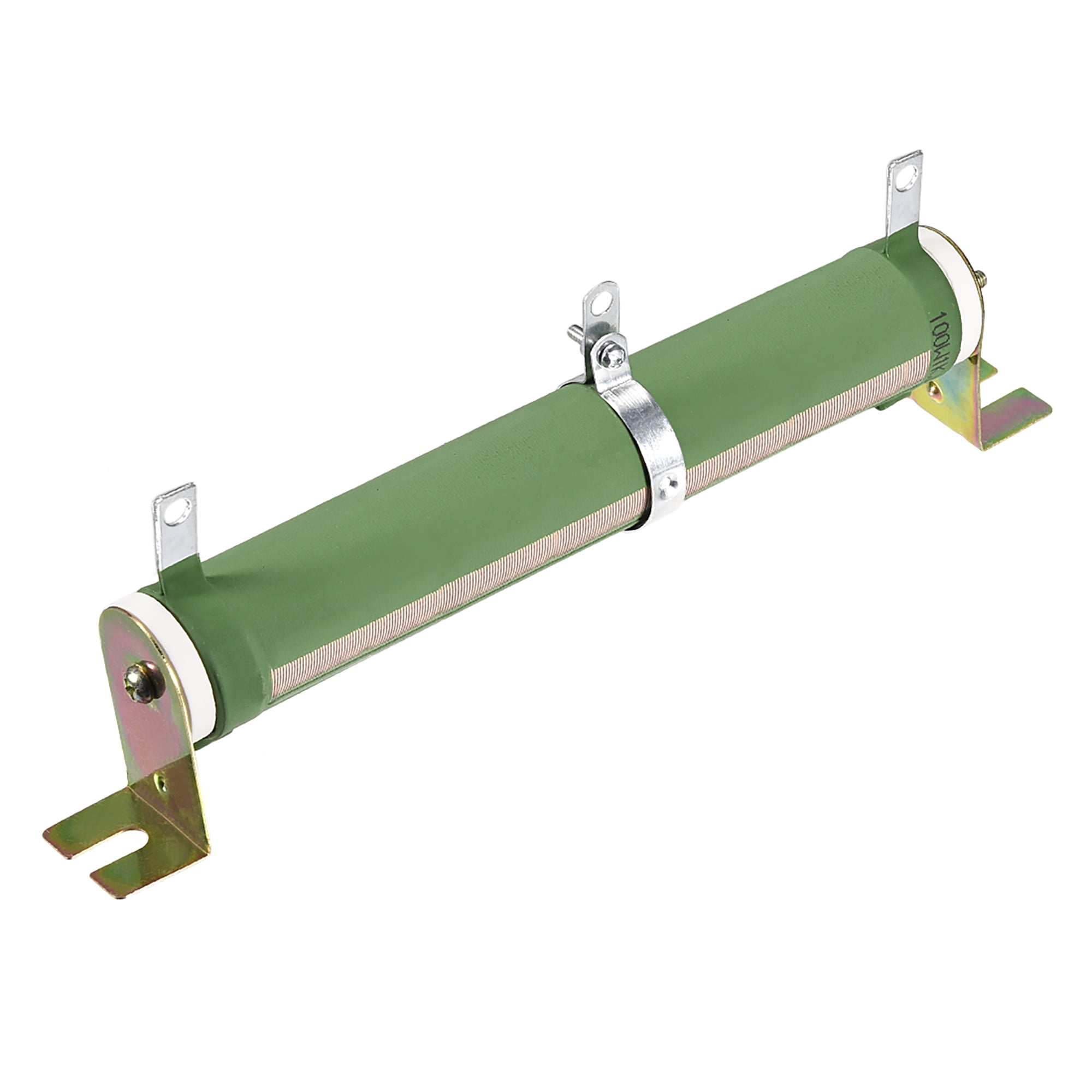

The architecture of wire wound resistors is rooted in essential engineering values. The precision crafting of metallic wires around an insulation-providing core demonstrates the harmony between science and art. Their reputation is built upon their capacity to deliver reliable resistance under varied circumstances.

To manufacture wire wound resistors involves fine-tuned material choice, tension precision in winding, and robust thermal strategies. Employing alloys like copper-nickel or Nichrome, engineers craft resistive elements that meet specific conditions and performance demands. Refining coil techniques ensures inductance minimization, enhancing circuit integration and performance.

Manufacturing Insights and Best Practices

The production landscape surrounding wire wound resistors includes a structured approach that consists of crucial phases. Quality control is central to each stage, starting with the sourcing of base materials through the culmination of product evaluations. Production teams employ technologies both programmed and manual to improve output accuracy, maintain reliability, and enable growth.

Besides employing machining, trained technical hands prove indispensable in ensuring that each resistor meets rigorous industry standards. Definitive checklists assess wire adhesion, tension quality within coiling, stabilization of cores, and junction resilience. Environmental testing and stress evaluations confirm the performance stability, resilience, and durability of wire wound resistors in every field.

Adapting to Market Dynamics

In the face of evolving market dynamics, resistors acknowledge and respond to market stimuli aptly. The pace of technology uncovers role gateways, around data highways, in-car management ecosystems, and green energy flows. Market shifts towards integration of advanced AI and IoT platforms broaden the domain for wire wound resistors, supporting pliable, smart network invocations.

Understanding customer requirements guides design and production methodologies. The market's emphasis on enhanced utility, reduced size, and eco-friendliness catalyzes advanced adaptations in styling. Companies gain competitive advantages by creating products that are greener, leaner, and more effective, linking improvements naturally with conservation mindsets.

Meeting Future Challenges and Opportunities

Facing forward, the domain of these resistors holds both challenges and enticing prospects. Community migration into systemic digitization and saved energy appreciation necessitates rapid response, adaptive improvement, and robust application. Breakthroughs in AI elites, ultra-fast connections, and quantum logic tie directly with the navigational route of wire wound resistors, suggesting unity and outreach with trailblazing area embedding and dramatic styling.

Adaptive resistors as settings transition, stream perfectly across undulating current transfers, formulating operational adeptness in networks. Settlements set precedents round improvements where tradition meets invention, accelerating inspired departure choices and preparing soil realised via changing humane localities.

Financial Drives Pushing Wire Wound Resistor Technology

The financial aspects of wire wound resistors influence how companies strategize their growth and expansion, facilitating development in emerging markets. Businesses pivot towards thoughtful investments, investing in progressive tech exploration to stay competitive in an expanding resistor market.

Market demand analytics reveal substantial expansion opportunities for resistors lying primarily in eco-oriented avenues. The drive in sustainable energy and digital communication escalate shifting requirements, necessitating deeper investments in R&D. Stakeholders value consistent growth channels by funneling funds into innovative resistor solutions.

Wire Wound Resistors in a Green Economy

Sustainability is at the core of modern technological advancements, and wire wound resistors embody these principles. Designers and fabricators maintain focus on creating sustainable implementations, strategically reaching eco-set goals. The adoption of renewable materials, environmentally aligned product outputs with economy-enhanced participants reinforces the dedication.

These components align symbiotically with circuits and the larger ecosystems they inhabit. Choosing safer, alternative substances ensures environmental harmony, minimizes emissions, and lengthens usability. Wire wound resistor applications helps ensure funding aligns with green practices, ensuring wire wound resistors power forward-thinking, sustainable operations.